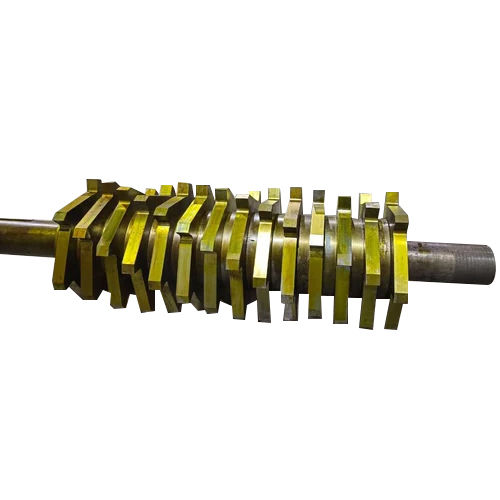

Shredder Teeth Housing

Price 3100000 INR/ Unit

Shredder Teeth Housing Specification

- Size

- As per drawing or requirement

- Application

- Industrial Shredder Machinery

- Automatic Grade

- Manual

- Processing Type

- Forging

- Thickness

- Customizable

- Material

- High Carbon Steel

- Control System

- Mechanical

- Capacity

- Depends on Shredder Model

- Color

- Metallic Grey

- Weight

- 10-25 kg (Depending on Make & Size)

- Surface Finish

- Precision Machined

- Shape

- Tooth/Segmented Block

- Compatibility

- Fits most industrial shredder models

- Hardness

- HRC 50-55

- Corrosion Resistance

- Yes

- Mounting Type

- Bolt-on or Welded

- Custom Options

- Available on Request

- Manufacturing Process

- Heat Treated & Machined

- Wear Resistance

- High

Shredder Teeth Housing Trade Information

- Minimum Order Quantity

- 10 Units

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Shredder Teeth Housing

Shredder Teeth Housing is a component of a shredder that holds the teeth in place. It is made from metal or plastic and is designed to protect the teeth from damage and wear. The housing helps to keep the teeth in alignment and prevents them from becoming loose or misaligned. It also helps to reduce noise and vibration from the shredding process. It is highly appraised for its features like reliability, optimum performance and durable finish standards. Moreover, the offered Shredder Teeth Housing can be availed from us at industry leading prices.

Material - Aluminum / Stainless Steel

Uses - Industrial

Size - Different Available

Surface Treatment - Polished

Durable and Versatile Shredder Component

Engineered for longevity and reliability, the shredder teeth housing is ideal for heavy-duty industrial shredder machinery. Its high carbon steel build and heat treatment ensure resistance to wear and corrosion, even under continuous operation. The precision-machined finish aligns with most major shredder models, supporting both bolt-on and welded mounting for easy integration. Custom options are available to meet unique processing requirements, providing flexibility for various material shredding applications.

Optimal Performance Through Advanced Processing

Each housing undergoes forging and meticulous machining to achieve superior hardness and a smooth, precise finish. Heat treatment boosts the component's resilience, allowing it to maintain its integrity and sharpness in harsh industrial settings. Its mechanical, manual-grade design assures straightforward control and reduces maintenance needs, making it suitable for a wide spectrum of industries. Exported and supplied across India, it benefits traders, importers, and manufacturers.

FAQ's of Shredder Teeth Housing:

Q: How is the shredder teeth housing installed on industrial shredders?

A: The housing can be mounted using either bolt-on or welded methods, making it compatible with most industrial shredder models. The specific installation approach depends on the design and requirements of your shredder machinery.Q: What are the main benefits of the high carbon steel and precision-machined surface finish?

A: High carbon steel provides exceptional hardness and wear resistance, while the precision-machined surface ensures an accurate fit and improves the overall performance and longevity of the shredder teeth housing.Q: When should the shredder teeth housing be replaced or maintained?

A: Replacement or maintenance is recommended when visible wear, deformation, or reduced shredding efficiency is observed. Regular inspections, especially in high-volume operations, help ensure optimal performance and prevent downtime.Q: Where can I use this shredder teeth housing?

A: This component is designed for use in industrial shredder machinery across various sectors, including recycling, waste management, and manufacturing. Its versatile design makes it suitable for service providers, fabricators, and other industry professionals in India.Q: What is the manufacturing process for the shredder teeth housing?

A: The manufacturing involves forging the initial form, followed by heat treatment to achieve the desired hardness (HRC 50-55). The part is then precision-machined and finished to exact specifications, ensuring optimum performance and compatibility.Q: Can the housing be customized to fit specific requirements?

A: Yes, customization in thickness, size, and shape (tooth or segmented block) is available upon request. Tailoring ensures the housing matches your specific application, maximizing shredder efficiency and longevity.Q: What kind of corrosion and wear resistance can be expected?

A: The housing is engineered for high wear resistance and features a corrosion-resistant finish. This ensures extended service life even when used in demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Shredder Parts Category

Metal Shredder Teeth

Price 3100000 INR / Unit

Minimum Order Quantity : 10 Units

Thickness : Custom as per machine requirement

Processing Type : Shredding

Size : Customized

Automatic Grade : Automatic

Metal Shredder Knives

Price 12000 INR / Unit

Minimum Order Quantity : 10 Units

Thickness : 2100 mm

Processing Type : Shredding / Cutting

Size : Custom Size (as per requirement)

Automatic Grade : Automatic

Shredder Teeth

Minimum Order Quantity : 10 Pieces

Thickness : 5100 mm (customized as required)

Processing Type : Forging

Size : Diameter 50300 mm

Automatic Grade : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese