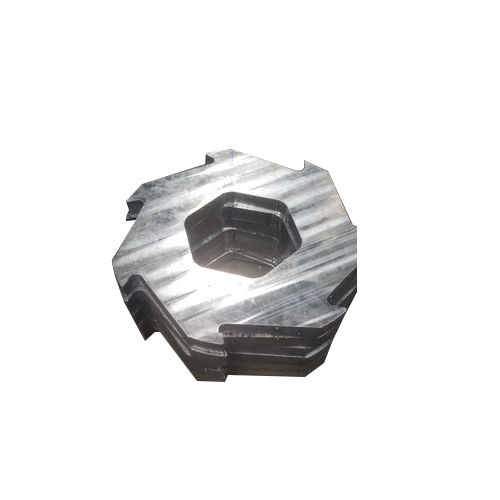

Metal Shredder Knives

Price 12000 INR/ Unit

Metal Shredder Knives Specification

- Material

- High Alloy Steel

- Capacity

- 100-3000 kg/hr

- Motor Power

- 7.5-200 kW (varies by model)

- Application

- Metal Shredding, Scrap Processing, Recycling

- Processing Type

- Shredding / Cutting

- Thickness

- 2-100 mm

- Weight

- 20-500 kg (varies as per specification)

- Automatic Grade

- Automatic

- Color

- Metallic Silver

- Frequency

- 50/60 Hz

- Size

- Custom Size (as per requirement)

- Noise Level

- <85 dB

- Control System

- PLC Controlled

- Sheet Capacity

- 2-100 mm Thickness

- Voltage

- 220-440 V

Metal Shredder Knives Trade Information

- Minimum Order Quantity

- 10 Units

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Metal Shredder Knives

Metal Shredder Knives are used to cut and shred metal materials into smaller pieces. They are made of high-grade steel and are designed to be extremely durable & long-lasting. These knives are demanded in a variety of industries, including scrap metal recycling, automotive manufacturing, and metal fabrication. These are manufactured using the finest grade raw materials under the strict supervision of our technical experts in line with set industry standards. Additionally, our customers can easily avail these Metal Shredder Knives from us at rock bottom prices with no hassle.

Material - Aluminum / Stainless Steel

Uses - Industrial

Size - Different Available

Surface Treatment - Polished

Precision Engineering for Superior Cutting Performance

Each shredder knife is crafted using high alloy steel and hardened through vacuum or induction processes. The result is a precisely sharpened, durable blade with an edge angle optimized for sustained maximum sharpness. These knives are engineered for continuous use in tough metal shredding applications, consistently delivering clean and efficient cuts.

Customizable Design to Suit Varied Requirements

Choose from serrated or plain blades according to your specific processing needs. Our knives are offered in multiple sizes, thicknesses, and finishes, all tailored to match your equipment and operational demands. Special surface treatments are also available for increased corrosion resistance in harsh environments.

Reliable Performance and Simple Maintenance

Benefit from long service life owing to robust materials and advanced manufacturing techniques. Each knife is designed for easy resharpening and interchangeability, facilitating maintenance and reducing downtime. The included PLC-controlled system further enhances operational efficiency and safety.

FAQs of Metal Shredder Knives:

Q: How do I select the right shredder knife design for my application?

A: Selection depends on your processing requirementschoose serrated blades for aggressive cutting of tougher materials, or plain blades for cleaner, precise cuts. Our knives can be customized in size and edge design to ensure optimal compatibility and performance.Q: What benefits does the high alloy steel material offer for shredder knives?

A: High alloy steel provides excellent toughness, wear resistance, and structural integrity, contributing to longer service life and sustained sharpness even in heavy-duty metal shredding and recycling operations.Q: Where are these metal shredder knives typically used?

A: They are widely used in metal shredding, scrap processing, and recycling industries across India, compatible with a broad range of shredder brands and models supplied to manufacturers, service providers, and processing facilities.Q: How easy is it to maintain and resharpen the shredder knives?

A: Maintenance is straightforward. Thanks to their engineered geometry and high durability, the knives can be easily resharpened, ensuring consistent performance and minimizing downtime.Q: What is the process for ordering knives in custom sizes and specifications?

A: Simply provide your size, thickness, and technical requirements when placing an order. Our team will manufacture blades to precise specifications, with a typical lead time of 24 weeks depending on order size.Q: What measures are taken to improve corrosion resistance of the blades?

A: Blades receive precision surface grinding and polishing, with the option for special surface treatments that significantly boost corrosion resistance, particularly valuable in aggressive or moist processing environments.Q: What packaging options are available for the shredder knives?

A: Standard packaging is durable wooden cases, but custom packaging is also available upon request to ensure secure delivery tailored to your logistical needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Shredder Parts Category

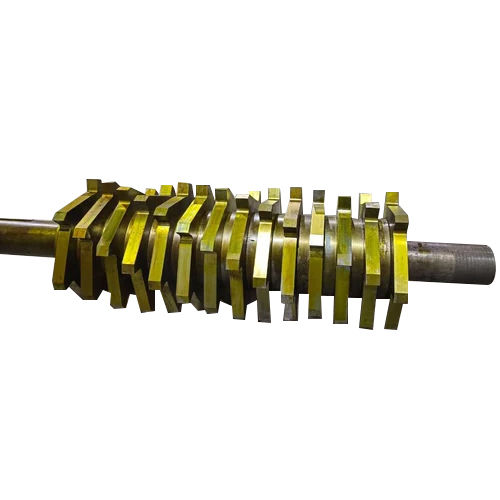

Metal Shredder Teeth

Price 3100000 INR / Unit

Minimum Order Quantity : 10 Units

Control System : PLC Based

Size : Customized

Automatic Grade : Automatic

Color : Silver/Grey

Shredder Teeth

Minimum Order Quantity : 10 Pieces

Control System : PLC Controlled

Size : Diameter 50300 mm

Automatic Grade : Automatic

Color : Silver/Grey/Customized

Shredder Teeth Housing

Price 3100000 INR / Unit

Minimum Order Quantity : 10 Units

Control System : Mechanical

Size : As per drawing or requirement

Automatic Grade : Manual

Color : Metallic Grey

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese