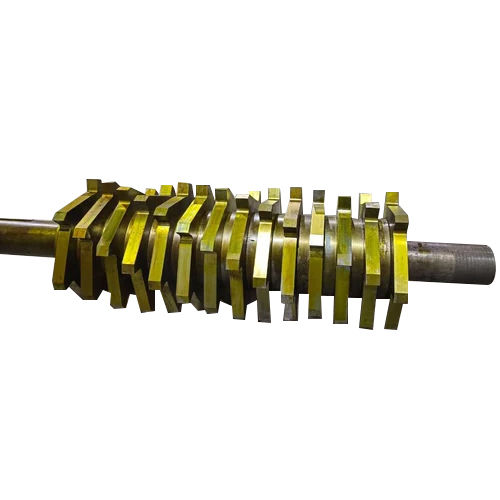

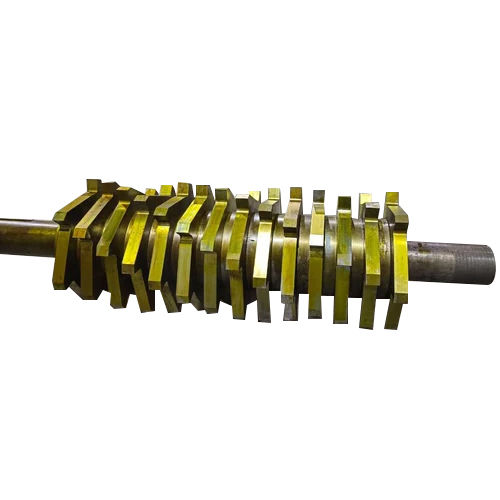

Metal Shredder Teeth

Price 3100000 INR/ Unit

Metal Shredder Teeth Specification

- Voltage

- 380-415 V

- Capacity

- 0.5-20 TPH (varies as per model)

- Control System

- PLC Based

- Size

- Customized

- Weight

- 10-50 kg per tooth (varies with size)

- Color

- Silver/Grey

- Frequency

- 50 Hz

- Processing Type

- Shredding

- Automatic Grade

- Automatic

- Application

- Industrial Metal Shredders

- Noise Level

- Less than 80 dB

- Sheet Capacity

- Up to 80 mm thickness (depending on machine)

- Motor Power

- 30-150 kW (varies as per requirement)

- Material

- Alloy Steel / Manganese Steel

- Thickness

- Custom as per machine requirement

- Corrosion Resistance

- Yes

- Tooth Profile

- Serrated / Hooked / Custom

- OEM Support

- Available

- Heat Treatment

- Induction/Through Hardened

- Surface Hardness

- HRC 50-65

- Compatibility

- Fits rotary and twin-shaft shredders

- Manufacturing Process

- Precision Casting & CNC Machining

- Mounting Method

- Bolt-On / Weld-On

- Service Life

- High (depends on material processed)

- Replacement Interval

- Depends on material hardness and operating hours

Metal Shredder Teeth Trade Information

- Minimum Order Quantity

- 10 Units

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Metal Shredder Teeth

Metal Shredder Teeth are the cutting tool used in industrial shredding machines to shred metal scrap into smaller pieces. These are made from high-grade steel and have ability to withstand the extreme forces of metal shredding. The teeth are usually sharpened and hardened to ensure they remain sharp & effective for a long time. They are also designed to reduce the amount of energy required to shred metal, making them more efficient and cost-effective. Additionally, our offered range of Metal Shredder Teeth are easily accessible in different specifications at reasonable cost.

Material - Aluminum / Stainless Steel

Uses - Industrial

Size - Different Available

Surface Treatment - Polished

Rugged Durability and Superior Cutting

Designed to handle demanding environments, these shredder teeth deliver exceptional wear resistance and high hardness. The combination of induction or through hardening, coupled with precise casting and machining, enables them to process metal sheets up to 80 mm thick, prolonging service life even with constant heavy-duty use.

Flexible Customization and Easy Installation

Select from various tooth profiles-serrated, hooked, or custom-to match your shredding requirements. Sizes, weights, and mounting styles are customizable, ensuring compatibility with a broad range of rotary and twin-shaft shredders. Installation is straightforward with bolt-on or weld-on methods, streamlining replacement and maintenance.

FAQ's of Metal Shredder Teeth:

Q: How are metal shredder teeth mounted onto the shredder?

A: Metal shredder teeth can be fitted using either a bolt-on or weld-on mounting method. The mounting style is chosen based on machine compatibility and operational requirements for easier installation and replacement.Q: What profiles of shredder teeth are available, and which should I choose?

A: You can select from serrated, hooked, or custom tooth profiles. The optimal profile depends on the type and thickness of metal being processed-the serrated and hooked profiles are suited for most industrial shredding needs, while custom profiles can be made for specialized applications.Q: When should metal shredder teeth be replaced?

A: Replacement intervals depend on the hardness of processed material and operating hours. Regular inspection is advised, and teeth should be replaced when you notice significant wear, reduced shredding efficiency, or visible damage.Q: Where can these shredder teeth be used?

A: These teeth are designed for rotary and twin-shaft shredders across various industrial applications in India, serving fabricators, manufacturers, recyclers, dealers, and other metal processing professionals.Q: What manufacturing processes are involved in making the shredder teeth?

A: Each tooth is manufactured through precision casting and CNC machining for tight tolerances, followed by induction or through hardening to boost surface hardness and durability. Corrosion-resistant treatments are also applied.Q: How does the heat treatment and hardness of these teeth benefit usage?

A: Induction or through hardened teeth with surface hardness ratings of HRC 50-65 provide excellent abrasion resistance, ensuring prolonged operational life and minimizing maintenance costs, especially when processing hard or abrasive metals.Q: What support is available for OEM or custom requirements?

A: OEM support is provided with options for custom sizing, profiles, weight, and thickness to fit specific machine models or custom-built shredders. Our team can assist with technical guidance to ensure optimal integration.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Shredder Parts Category

Metal Shredder Knives

Price 12000 INR / Unit

Minimum Order Quantity : 10 Units

Material : High Alloy Steel

Thickness : 2100 mm

Application : Metal Shredding, Scrap Processing, Recycling

Automatic Grade : Automatic

Shredder Teeth

Minimum Order Quantity : 10 Pieces

Material : Alloy Steel (High Carbon/Chromium)

Thickness : 5100 mm (customized as required)

Application : Metal, Plastic, Paper, Tyre and Waste Shredding

Automatic Grade : Automatic

Shredder Teeth Housing

Price 3100000 INR / Unit

Minimum Order Quantity : 10 Units

Material : High Carbon Steel

Thickness : Customizable

Application : Industrial Shredder Machinery

Automatic Grade : Manual

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese