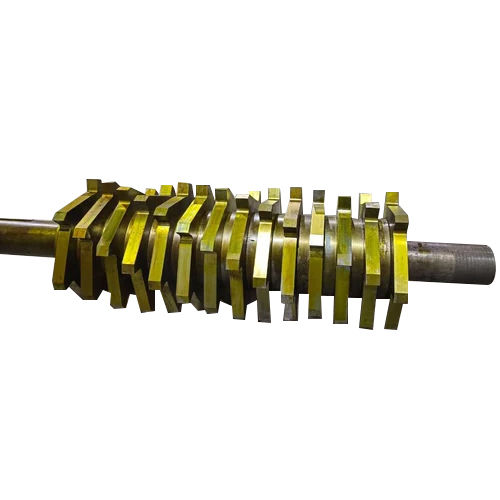

Shredder Teeth

Shredder Teeth Specification

- Weight

- Varies by size (Standard 10-150 kg per tooth)

- Voltage

- 220V / 380V / 440V

- Motor Power

- Customizable (Standard 5-50 HP)

- Material

- Alloy Steel (High Carbon/Chromium)

- Control System

- PLC Controlled

- Capacity

- 500-5000 kg/hr

- Thickness

- 5-100 mm (customized as required)

- Size

- Diameter 50-300 mm

- Sheet Capacity

- Depends on model/diameter (Standard: 10-50 sheets)

- Automatic Grade

- Automatic

- Processing Type

- Forging

- Application

- Metal, Plastic, Paper, Tyre and Waste Shredding

- Noise Level

- < 75 dB

- Frequency

- 50/60 Hz

- Color

- Silver/Grey/Customized

- Corrosion Resistance

- Anti-corrosive coatings optional

- Replacement Cycle

- Depends on usage and material type shredded

- Mounting Type

- Bolt-on/Keyed/Fitted

- Tooth Pitch

- Custom according to application

- Edge Profile

- Straight, Hooked, or Serrated

- Shape / Design

- Multi-tooth spiral or segmental

- OEM/ODM Service

- Available

- Surface Hardness

- HRC 50-62

- Manufacturing Technique

- Precision CNC Milling and Cutting

- Heat Treatment

- Quenching and Tempering

Shredder Teeth Trade Information

- Minimum Order Quantity

- 10 Pieces

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Shredder Teeth

Material - Aluminum / Stainless Steel

Uses - Industrial

Size - Different Available

Surface Treatment - Polished

Metal Shredder Teeth are the cutting tool used in industrial shredding machines to shred metal scrap into smaller pieces. These are made from high-grade steel and have ability to withstand the extreme forces of metal shredding.

Advanced Design for Effective Shredding

Our shredder teeth feature a multi-tooth spiral or segmental shape, maximizing material engagement and improving cutting efficiency. The custom edge profiles-straight, hooked, or serrated-cater to various shredding requirements, offering versatility across multiple industries such as metal, plastic, and waste processing.

Durable Construction and Customized Performance

Manufactured from alloy steel with high carbon and chromium content, every tooth undergoes controlled quenching and tempering, achieving a reliable surface hardness of HRC 50-62. Precision CNC milling ensures accurate fit and consistent performance, while customizable motor power and voltages address unique operational needs.

Flexible Solutions and OEM/ODM Support

We offer multiple mounting options-bolt-on, keyed, or fitted-for easy installation and replacement, along with anti-corrosive coatings for extended life. Our OEM/ODM service enables design modifications for specific applications, ensuring the ideal solution whether you are a manufacturer, supplier, dealer, or service provider.

FAQ's of Shredder Teeth:

Q: How are shredder teeth installed and replaced?

A: Shredder teeth are designed for bolt-on, keyed, or fitted mounting, making installation and replacement straightforward. The replacement cycle depends on material type and machine usage; heavy shredding typically requires more frequent replacement.Q: What are the benefits of multi-tooth spiral or segmental designs?

A: These shapes increase the shredding surface area and deliver smoother, more consistent material reduction, supporting efficient operation in applications ranging from metal recycling to paper and tyre shredding.Q: When should anti-corrosive coatings be chosen for shredder teeth?

A: Anti-corrosive coatings are recommended for environments with high moisture, chemicals, or corrosive materials. They extend the lifespan of the teeth, especially in continuous or tough-duty operations.Q: Where can customized shredder teeth be procured in India?

A: Customized shredder teeth are available through manufacturers, suppliers, dealers, distributors, exporters, and retailers across India. Consult with an OEM/ODM provider to specify your requirements for size, edge profile, and material.Q: What is the role of heat treatment and surface hardness in shredder teeth durability?

A: Quenching and tempering processes, along with a surface hardness of HRC 50-62, enhance wear resistance, toughness, and longevity, reducing downtime and maintenance costs for the shredding equipment.Q: How does the PLC control system contribute to operational efficiency?

A: The PLC-controlled automatic grade ensures precise operation, real-time monitoring, and optimized shredding cycles, improving productivity and safety for industrial shredding applications.Q: What determines the sheet capacity and processing rate of the shredder teeth?

A: Sheet capacity and processing rate depend on the chosen shredder model and tooth diameter, with standard capacities accommodating 10-50 sheets and throughput ranging from 500 to 5000 kg/hr for various material types.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Shredder Parts Category

Metal Shredder Knives

Price 12000 INR / Unit

Minimum Order Quantity : 10 Units

Automatic Grade : Automatic

Processing Type : Shredding / Cutting

Color : Metallic Silver

Application : Metal Shredding, Scrap Processing, Recycling

Metal Shredder Teeth

Price 3100000 INR / Unit

Minimum Order Quantity : 10 Units

Automatic Grade : Automatic

Processing Type : Shredding

Color : Silver/Grey

Application : Industrial Metal Shredders

Shredder Teeth Housing

Price 3100000 INR / Unit

Minimum Order Quantity : 10 Units

Automatic Grade : Manual

Processing Type : Forging

Color : Metallic Grey

Application : Industrial Shredder Machinery

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese