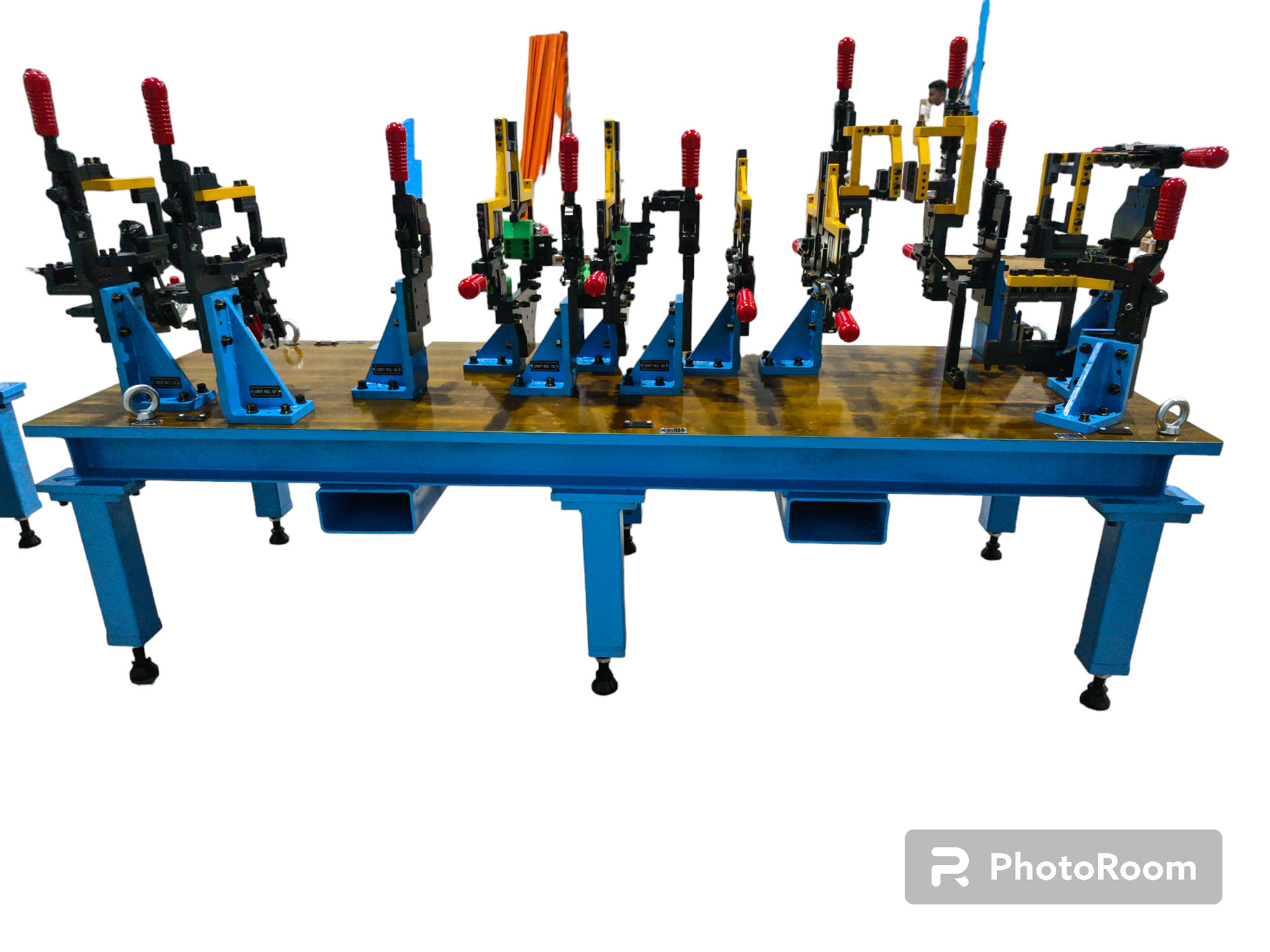

Spot Welding fixtures

Price 450000 INR/ Number

Spot Welding fixtures Specification

- Working Process

- Suitable for spot welding automation and manual process

- Die Head

- Interchangeable/Fixed with precision mounting

- Life Span

- Up to 5 years (depending on usage and maintenance)

- Shaping Mode

- Custom as per welding requirements

- Material

- Hardened Tool Steel, Alloy Steel, or as per customer requirement

- Application

- Sheet Metal Assembly, Automotive Body Parts, Industrial Welding

- Hardness

- 45-60 HRC

- Tolerance

- 0.05 mm

- Fixture Weight

- 15-80 kg depending on size and application

- Surface Treatment

- Nickel plated / Zinc coated / Black oxide as per requirement

- Mounting Type

- Base plate with clamp mechanism / custom mounting provision

- Customization

- Available as per client drawing or sample

- Production Capacity

- 30-80 fixtures per month

- Number of Welding Points

- 2-12 per fixture, as specified

- Precision Alignment

- Dowelling and locking for repeatability

- Dimensions

- Customized per jig and product specification

- Electrode Holder

- Copper alloy with insulation bush

- Corrosion Resistance

- High, due to treated surfaces

About Spot Welding fixtures

We have Designing & Manufacturing the welding fixture, we inhouse facility for checking fixture and trail & Testing, we have also designing Robotic welding cell & Manufacturing with Interlock Welding fixture, we have consider poka-yoke for Mechanical & electricalsSuperior Surface Protection

Spot welding fixtures are available with surface treatments like nickel plating, zinc coating, or black oxide, significantly increasing resistance to corrosion. This ensures the fixtures maintain integrity and reliability, even in demanding industrial environments, while prolonging operational lifespan and minimizing maintenance.

Customization for Your Application

Each fixture can be fully customized according to client drawings or product samples. From dimensions and mounting types to the number of welding points and even the electrode holder design, every detail can be matched to your specific process and production needs.

Precision & Repeatability

Our fixtures utilize dowelling and locking mechanisms for precise alignment. This guarantees consistency and repeatability in spot welding operations, which is crucial for high-quality assembly in sectors such as automotive and industrial manufacturing.

FAQs of Spot Welding fixtures:

Q: How are spot welding fixtures customized according to client requirements?

A: Spot welding fixtures can be tailored to exact client drawings or product samples, including fixture dimensions, weight, number of welding points, mounting provisions, and material choices. This ensures the fixture seamlessly adapts to unique applications and workflow needs.Q: What surface treatments are available, and what are their benefits?

A: Available surface treatments include nickel plating, zinc coating, and black oxide. These finishes improve corrosion resistance, extend the life of the fixture, and provide reliable performance in harsh production environments.Q: Where are these spot welding fixtures typically used?

A: These fixtures are widely used in sheet metal assembly, automotive body manufacturing, and various industrial welding setups requiring precision alignment and multiple welding points.Q: What is the process for ensuring precision alignment and repeatability?

A: Precision alignment is achieved through the use of dowelling and locking mechanisms. These features secure the fixture in place for consistent and repeatable welding outcomes, essential for maintaining high-quality assembly standards.Q: What is the expected lifespan and maintenance of the fixtures?

A: The fixtures are designed for a lifespan of up to 5 years, depending on usage and routine maintenance practices. Regular inspection and proper handling can further extend durability and functional reliability.Q: What is the production capacity for these spot welding fixtures?

A: Production capacity ranges from 30 to 80 fixtures per month, depending on size, complexity, and customization needs. This allows for scalable supply to match varied industrial demands.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Welding Fixtures Category

Biw Welding fixtures

Price 200000 INR / Piece

Minimum Order Quantity : 10 Pieces

Hardness : HRC 2832 (as per requirement)

Working Process : Other, Automated Spot and Mig Welding Support

Material : Other, Mild Steel (MS), Alloy Steel, Hardened Plates

Tolerance : 0.05 mm

Robotic Welding Cell

Price 1650000 INR / Number

Minimum Order Quantity : 10

Hardness : Structural Frame: 4050 HRC

Working Process : Other, Automatic Welding by Programmable Robot Arm

Material : Other, HighGrade Steel Structure with Aluminum and Electronic Components

Tolerance : Welding Accuracy 0.5 mm

Spot Welding Fixture

Price 425000 INR / Unit

Minimum Order Quantity : 10 Units

Hardness : Hard

Working Process : Bending

Material : Steel

Spot Welding Fixture and Mig Welding Fixture

Price 350000 INR / Unit

Minimum Order Quantity : 10 Units

Hardness : Hard

Working Process : Bending

Material : Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese