Showroom

Auto Inspection Gauges are highly accurate measuring instruments used in the automotive manufacturing and assembly process to inspect and authenticate the quality, dimensions, and standards of various parts and components during the manufacturing, assembly, and post-assembly process. They help detect defects, anomalies, or variations in automobile parts before they are incorporated into automobiles or delivered to customers.

Jig Fixtures are used in the manufacture, woodworking, and metalwork processes to hold and position workpieces during operations that include drilling, cutting, welding, or assembly. Use makes these all-important in mass production, prototyping, and custom manufacturing processes, minimizing the probability of making mistakes by securely holding a workpiece and guiding the tools through the specific operations involved, which increases productivity.

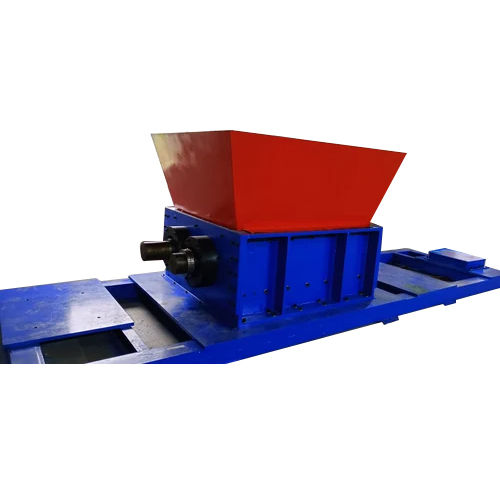

A Shredder Machine is a machine, that cuts materials into small pieces or strip pieces. Typically, shredding is done in order to dispose of and recycle materials, especially to provide privacy and security, or to prepare the materials for further processing. The most common uses of a shredder include disposing sensitive information including financial records, legal papers, tax returns, medical records, and personal information.

Welding Fixtures are tools or devices used to hold, align, and position workpieces correctly in welding operations. The welding fixture keeps workpieces tightly in place and aligned and ensures good weld quality with minimal errors and shortens production cycles. They are designed to ensure that components are correctly aligned, held in place, and protected while being welded.

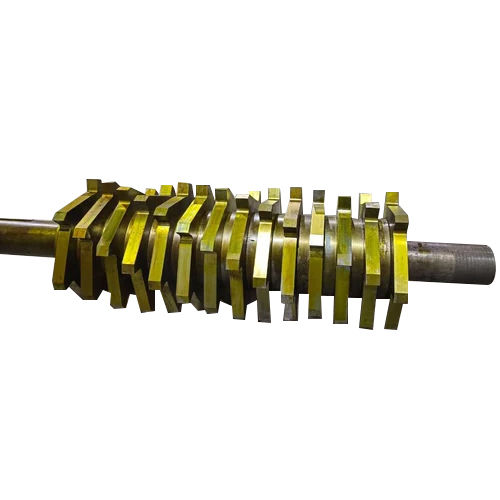

Shredder Parts is a collection of materials, that forms the shredder machine, either a paper shredder or one working with industrial materials, or even hard drive shredders. Together, they form a reliable and effective shredding process, whether being paper, plastic, or something rather tougher in the industrial/material categories. Knowing each's role would further help both in maintenance and repair, hence avoiding malfunctions in any shredder equipment.

A Hydro- Pneumatic Press uses both hydraulic and pneumatic power in concert to produce high force applicable to delicate operations and applications. The proper maintenance of the hydraulic system and the precision adjustment of the pneumatic unit ensure optimal working operations and longevity in the service of the press. These presses are required for different manufacturing operations, such as forming, stamping, punching, and assembling processes, where hydraulic force would be critically needed along with pneumatic assistance for proper functionality.

|

JP ROBOTICS & AUTOMATION LLP

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free